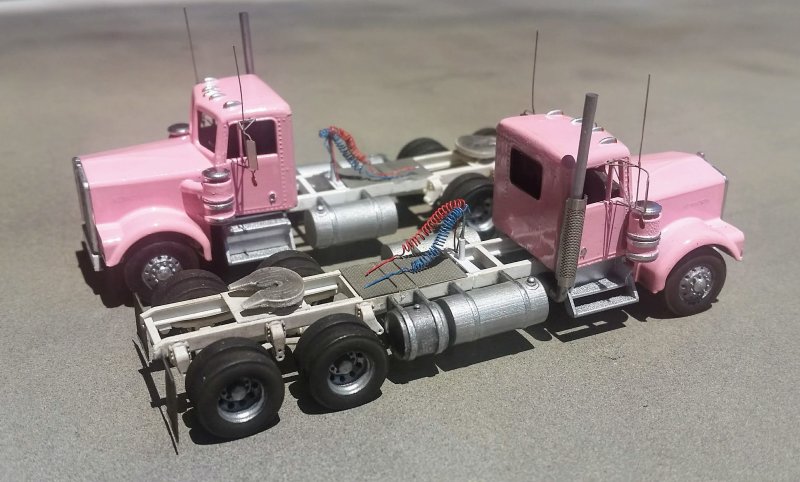

Athearn has made Freightliner cabover and Kenworth conventional semi-tractors for decades. Some years ago these were incorporated into the RTR line with new details such as mirrors, visors, windshield wipers and much better wheels and tires. The upgrades are nicely done and make excellent models that fit in well with other HO scale vehicle models.

I have always admired the quality of the tooling that has produced beautiful castings of these models over the years, in particular the cabs and grilles. Since I was a kid I have built many models using the Freightliner as a starting point, transforming it into a SBFA straight truck and a daycab among other conversions. When I stumbled across a couple cabs with grille sprues on eBay it occurred to me I hadn't taken on the Kenworth.

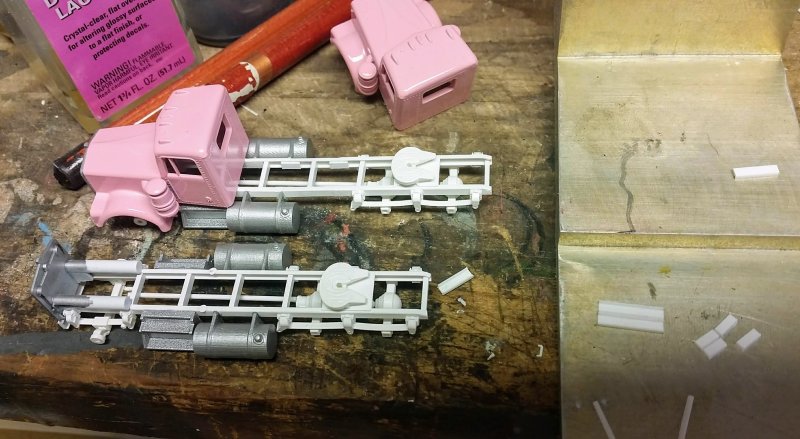

So the idea here was to use the best parts of the Athearn model (the cab and grille) and replace everything else either by scratchbuilding, substituting aftermarket parts or 3D printing new parts. The frames were scratchbuilt from Evergreen Scale Models no. 263 styrene channel and 0.040" x 0.080" styrene strip for cross members. I also used Plano Model Products no. 352 Chrome Tipped Mud Flaps, no. 375 Kenworth T600 Mirrors, and no. 369 Diamond Plate Crossover Platforms. The etched exhaust heat shields are from Masterbilt Models.

Several 3D printed parts were used on these models. I had already designed several variations on wheels and tires. I selected aluminum wheels with beauty caps over the hubs for these models. The suspension and Holland fifth wheel parts had already been designed and printed for upgrading several Lindberg Ford CL9000 daycab models, so I used spares from that project here. Over the course of this project I created new Kenworth steps and air breathers, hydraulic tanks, and different sizes of fuel tanks.

The paint scheme for these trucks is heavily inspired by local company McRyan Hauling, whose distinctive pink Peterbilts are very eye-catching.

Thursday, July 18, 2019

Autoracks

Seen one you seen 'em all.

My modeling efforts focus on Fort Worth in the late 80s, though I have been known to drift off on tangents at times. For as long as I can remember, General Motors has operated an assembly plant in Arlington, Texas between Dallas and Fort Worth on the former Missouri Pacific. In fact, many of my friends growing up had parents who worked at the Arlington assembly plant. During the 80s the Arlington plant built the GM G platform, including the Chevy Monte Carlo and the Olds Cutlass Supreme. In 1988 the plant was reconfigured to produce the D platform Cadillac Brougham and Fleetwood as well as the GMT400 truck platform.

Autoracks are one of those cars where every one of them looks the same. Until you start looking at them, that is.

So a quick rundown of the history of autoracks: Trailer Train Company is formed in 1956 to standardize piggyback equipment and simplify interchange between railroads. Frisco created the modern autorack using an 85' flatcar in 1959, which made transport of autos economical. Whitehead & Kales constructs its 10,000th autorack in 1966. By 1978 some autoracks are being delivered with shields, end door and roofs, but about 90% of autoracks remain unshielded. By 1983 Trailer Train's fleet of autorack cars numbers more than 22,000. Fifteen years later, TTX Company's fleet of autoracks included over 27,000 bilevel autoracks and more than 21,000 trilevel autoracks. [from "America's Driving Force: Modeling Railroads and the Automotive Industry" published by Wm, K, Walthers]

These cars were built to squeeze as much cargo as possible onto the already large 89'-4" long deck of the typical autorack flatcar. Tight clearances in the eastern United States demanded cars with a lower deck and Pullman Standard answered the call with their PLH21 flatcar featuring 61" wheelbase trucks with 28" diameter wheels.

|

| Walthers trilevel on PLH21A flat |

In order to prevent damage to the cargo, side shields were affixed to many existing autoracks and others received full enclosures. As this technology was developed many new designs appeared. Tri-fold doors and end screens were applied to many cars early on, but these designs were superseded by the Thrall radial door, which is by far the most common type of end door, Portec's slat-style door and Greenville Steel Car's RAVE (Rack Anti Vandalism Enclosure) door. There are many variations on the radial door that beg to be modeled. Some give clues as to how many racks are in the enclosed car while others have no openings for the rack ends. Early versions extended vertically only so far as the top of the autorack sides leaving the ends underneath the roof exposed. In the 21st century the tri-fold door has made a comeback and is standard on Auto-Max articulated cars as well as newly constructed 90' autoracks.

|

| Portec and GSC RAVE doors |

My modeling efforts focus on Fort Worth in the late 80s, though I have been known to drift off on tangents at times. For as long as I can remember, General Motors has operated an assembly plant in Arlington, Texas between Dallas and Fort Worth on the former Missouri Pacific. In fact, many of my friends growing up had parents who worked at the Arlington assembly plant. During the 80s the Arlington plant built the GM G platform, including the Chevy Monte Carlo and the Olds Cutlass Supreme. In 1988 the plant was reconfigured to produce the D platform Cadillac Brougham and Fleetwood as well as the GMT400 truck platform.

For my purposes, the plant was producing cars and needed lots of trilevel autoracks. There are three models of autorack currently produced in HO scale and one from a former manufacturer that will work for my needs: Walthers enclosed trilevel, Accurail open trilevel and Athearn Genesis open trilevel as well as the defunct Custom Rail enclosed trilevel. By the late 80s a majority of autoracks were enclosed so I have concentrated my efforts on the Walthers trilevel. I prefer enclosed cars because they prevent me from having to populate autoracks with expensive models, but I can deal with one or two.

With so many of these Walthers trilevel autoracks in the fleet it's easy to say, "seen one you seen 'em all." So I have endeavored to model those small differences that made some of the cars stand out from all the rest. I first noticed these differences when BNSF picked up a sizable share of the auto business in Texas and I started to see autoracks up close on a daily basis. The PLH21 low deck flatcar jumped out at me and I made a field trip after work to see one up close.

The photos led to drawings which led to 3D printed parts. I noticed three variations on the PLH21 deck: unmodified, modified with inspection holes/rectangular reinforcing plate and modified with inspection holes/trapezoidal reinforcing plate. I have equipped two models with the PLH21 sill parts so far with another one in the works.

|

| TTGX 850408 bilevel autorack on PLH21A flat |

The photos led to drawings which led to 3D printed parts. I noticed three variations on the PLH21 deck: unmodified, modified with inspection holes/rectangular reinforcing plate and modified with inspection holes/trapezoidal reinforcing plate. I have equipped two models with the PLH21 sill parts so far with another one in the works.

|

| PLH21 sill parts and National swing motion trucks added to Walthers trilevel |

Trucks are another big change I've noticed, but these don't much apply to my modeled era. Many autoracks are now equipped with National swing-motion trucks. I identified two spring pack versions of the 70-ton 33" wheel truck and one version of the 70-ton 28" wheel version. I plan to build a Union Pacific CA-11 caboose one day and the 33" wheel trucks will be used on that model, but they do look good on an autorack.

|

| National swing motion 70-ton trucks |

My Walthers trilevels all came with their "100-ton" truck and 28" wheels. This truck looks weird with its long wheelbase and small wheels.

All the stock trucks have been removed and have been replaced with ExactRail trucks or Athearn Impack car trucks with the original Walthers 28" wheels installed.

End doors are another area where it's easy to add variety. I've created a number of variations on the tri-fold door to match several prototypes as well as Portec and Greenville Steel Car slat-style doors.

|

| Stock 100-ton 70" wheelbase trucks on top, 3D printed 61" wheelbase 70-ton trucks below |

All the stock trucks have been removed and have been replaced with ExactRail trucks or Athearn Impack car trucks with the original Walthers 28" wheels installed.

|

| Athearn Impack car trucks equipped with Walthers 28" wheelsets |

End doors are another area where it's easy to add variety. I've created a number of variations on the tri-fold door to match several prototypes as well as Portec and Greenville Steel Car slat-style doors.

I have recently added some roof ends to my shop at Shapeways. I'm looking forward to adding these to my latest project, a Frisco trilevel with body-height radial doors.

Subscribe to:

Posts (Atom)