Real life kitbash: AC4400C4M AC four motor conversion from C44-9W ATSF 608

A big change in railroading was effective dynamic braking. As long as there was an occupied caboose at the rear of the train, train handling meant keeping the slack stretched to avoid throwing your conductor and brakeman out of their seats. To accomplish this the engineer would make a minimum reduction and drag the train over hogbacks and shallow valleys. As dynamic braking technology improved the timing couldn't have been better. New crew consist labor agreements and legislation made cabooses go away for most Class I trains. This freed up the engineer to control the slack without dragging brakes, something the railroads were very interested in because of the massive fuel savings potential, greater average speed, and a lower risk of sticking brakes, flat spots, hotboxes and other problems with the train.

Dynamic brakes had previously been more of a mountain grade feature to augment air braking on long downhill runs than a tool you'd use to control speed on flatter terrain. By themselves they weren't enough to keep heavy trains under control. But through the 70s and 80s the technology was developed to increase their effectiveness and to lower the minimum speed they were effective. With these new capabilities engineers were able to transition between throttle and dynamic braking frequently.

Back when dynamic brakes were used primarily on long descending grades, there weren't many scenarios where the diesel engine would be running hot and demanding cooling from the radiators at the same time the dynamic brakes were dissipating braking force in the form of releasing heat energy through the resistor grids. Therefore it made sense to locate the resistor grids near the radiator where you already had a large fan and intake grilles. But once the ability to transition frequently between throttle and dynamic braking was available, the diesel engine didn't have time to cool while the resistor grids kept the radiator hot. This led to relocating the dynamic brake resistor grids and cooling fans ahead of the diesel engine, first seen on Burlington Northern's second order of B30-7A cabless booster units and C36-7s delivered to Missouri Pacific and Norfolk & Western.

As the use of dynamic brakes moved outside the realm of mountain grades, they became more powerful and more cost-effective to use. Along with the adoption of computer control systems of the diesel engine and electrical systems, design elements of the locomotive had to change to hold up under the new normal extreme operating conditions. These improvements in part led to the Dash 8 series, the wildly successful Dash 9 series and finally to today's Evolution series.

GE wasn't alone in innovation. EMD also computerized their engine and electrical systems around the same time. Like GE, EMD took a new approach with the dynamic brakes on their 50 series locomotives and again with the 80 and 90 series, relocating and improving them each time.

When GE unveiled a new locomotive series it looked like each new design was nothing more than the old Universal series locomotive under layers of bolted on parts. Let's face it: aesthetics were never part of GE's design philosophy when it came to locomotives. Form follows function period. Compare this to General Motors' Electro-Motive Division, where styling was part of the identity of the company from the Corvette to the Cadillac. Look at the homely hodgepodge of a locomotive, the GE B39-8 demonstrator. Compare this to the sleek and aerodynamic EMD GP60 demonstrator, its direct competitor. If looks matter, it's not even a fair fight. But when it came to achieving fuel efficiency, higher horsepower and putting that horsepower to the rail, GE won.

EMD 7 GP60 Demonstrator

As a modeler it always looked to me like GE simply kitbashed their latest design using parts from previous models. The basic Universal series locomotive had a distinctive cab with a rounded roof, a snub nose and a plain long hood with a rounded roof contour echoing the lines of the cab. This plain hood was punctuated with the occasional grille and a large radiator at the rear. The improved Dash 7 series was just like the Universal series, but with the largest of the large U33 radiators extending out over the walkway. As production carried on Dash 7s had the dynamic brake housing separated from the radiator and moved to a "bump" in the auxiliary cab roof. This bump carried through to the early Dash 8 series and was incorporated into a boxy hood between the operator cab and the engine compartment. U33 radiators were changed out for larger angled Dash 8 radiators.

The Dash 9 series saw the end of the four axle diesel, the standard cab, and the simple angled fuel tank with reservoirs at each end. But with that end came the adoption of large outside coil spring trucks and optional AC traction technology. In the midst of all that was the old Universal series hood covering the engine compartment. Everything else had changed, but that hood was still there (though angled instead of rounded). That feature finally went away with the Evolution Series, along with the Dash 8 radiator, but still around were the comfort cab, the Dash 8 auxiliary cab, the big trucks and the Dash 9 fuel tank.

The apparent modular nature of GE locomotives makes them ideal modeling subjects, especially with so many nicely detailed and great running models from Atlas. The U23B drive and body shell can be combined with the U33C drive and shell to build a U33B, U36B or a U23C. Before Atlas released the B23-7 and B30-7 models, I cut down a C30-7 shell into a B23-7. I had enough trouble with the Bachmann drive -- in particular the trucks -- that I stopped work on the model. The release of the Atlas B23-7 model finally stuck a fork in this project. But the concept was proven, that with enough slicing and dicing the raw materials were there in the Atlas shell parts to build a variety of models.

GE B23-7 from Atlas C30-7 long hood and nose, Atlas U23B cab and Bachmann B23-7 frame and sill

Of course 3D printing has opened up an entirely new set of possibilities using modular components to either cut into the Atlas shell or even replace entire parts. I mentioned building a model of a late C36-7 in my Norfolk & Western clasp truck blog. At the time I didn't address the stacked horizontal radiator intake grilles because there was no good source of the grilles. I couldn't figure out how to scratchbuild them or where I might get something reasonably close to cut in. Besides, the model is painted black. Who can even tell? I finished the model in January 2014 and moved on.

GE C36-7 as NW 8534 from Atlas C30-7, Smokey Valley and Hi-Tech Details parts

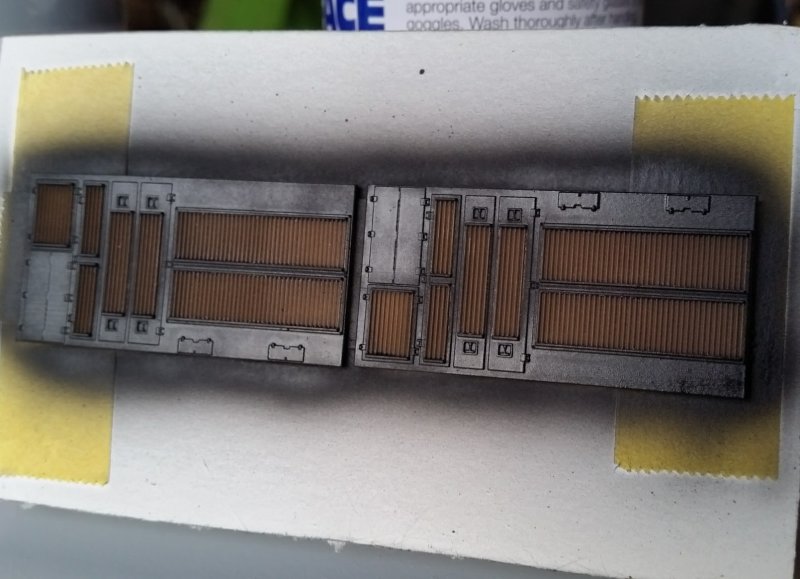

A couple years later it occurred to me I could use the translucent nature of 3D printed acrylic parts to model the see-through nature of the corrugated screen grilles on GE locomotives. I drew up some replacement panels for the area under the radiators on the Atlas model and printed them. I painted them lightly with a dirty brown color, just enough to tint the grilles, then I masked the grilles front and back and painted the rest of the parts the black body color. Installed on the model they look great. If you hold the model up to a light you can see the light come through the grilles. Of course the large metal weight mounted to the frame blocks most of the light, but as a concept it's solid.

NW C36-7 radiator parts available from my Shapeways store

Since then I've designed other hood parts, fuel tanks, air reservoirs, cabs and frames. I'm even working on a body kit for Burlington Northern B30-7A booster units. Where will this end? Who knows? But I'm pretty far from the end right now. There are a lot of models and variations to cover -- and kitbash -- yet.

Good article, I'm a big fan now but wasn't always because it took a long time for 5he butt hurt to go away from the dethroning of EMD LOL. Good loyal follower I am lol. The C36-7 and C39-8 were t by e locomotives that enabled GE to grab the reins and never look back as EMD did to Alco. EMD has the means to grab the Trophy back today if they'd get rid of that hillbilly running it. I mean come on, Caterpillar has got the big balls man, somebody in the company needs to push his sexitary off him and take a look what's going on in the train world. Lol, now that GE sold I keep waiting for a new locomotive to surface out of progressive rail. Good article you got here, hat sir. Thanks for the information ... BRIAN

ReplyDelete