Norfolk & Western may be best known as the last railroad to retire their steam locomotives and replace their locomotive fleet with diesels. In the diesel era they were known as one of the last railroads (along with future merger partner Southern Railway) to purchase high short hood locomotives. When other railroads had embraced the idea of using a J-relay valve in the locomotive's independent brake system to produce greater brake cylinder pressure against a single brake shoe per wheel, Norfolk & Western stayed the course of using clasp type brakes and lower operating brake cylinder pressure. Evidence of this could be seen in the trucks used on N&W's six axle diesels. The twelve brake shoes per truck gave them a distinctive look.

I modified a couple Athearn SD40-2s to have clasp type brakes a few years ago. I covered those models in my blog here. The modification to the Athearn trucks is pretty easy and it can be done using either Blomberg trucks or Flexicoil switcher trucks to donate the brake shoes, although the Flexicoil switcher trucks will also provide the brake cylinder with the long push rod. It also helps that the Athearn sideframes are made from styrene, which is easy to cut and splice and glue together.

Triple clasp sideframes on Athearn RTR SD40-2

It's another story entirely if you're modeling anything GE, with the exception of the last order of C36-7s. In fact, not having the ability to model the Adirondack clasp type sideframes found on N&W's U30Cs, C30-7s and early C36-7s is the reason I chose to model one of the later C36-7s. Atlas originally made two different sideframes for the U33C and C30-7 models, which they called GSC and Adirondack sideframes after the casting foundry of each prototype. However, Atlas mislabeled the parts which caused great confusion for people trying to get the "correct" version for a particular model.

Atlas GSC C30-7 sideframe

Atlas Adirondack C30-7 sideframe

When Atlas came out with the U30C, another style of sideframe was offered. This time it was a later Adirondack sideframe with low mounted brake cylinders.

This style of sideframe holds the most promise for someone wanting to build some N&W clasp style sideframes. It has the correct shape overall as well as in the area over the brake cylinder lever. Unfortunately the brake cylinder lever at the top of the sideframe exists only to tie onto the handbrake chain, so this shape is only found on the left axle when looking straight at the sideframe. You'd need this shape along with a mirror image of it to cut and splice these sideframes into models of the clasp type, and that's assuming you could actually get the slick engineering plastic the sideframes are cast in to glue back together.

These sideframes, like the National Uni-Truck II (found on some Trailer Train Front Runners, Southern's Autoguard articulated autoracks and under the ends of Burlington Northern's Trough Train articulated coal hoppers) represented something of a holy grail for me. Once I became familiar with the idea that 3D printing could reproduce fine enough details in a durable enough material for modeling I knew I had to take up the challenge to create a CAD model of them.

It's one thing to decide to make a 3D model of something rare and unique and quite another to find enough reference material to make it happen. What was frustrating about these sideframes (and the Uni-Truck II) was they really weren't that rare, they just weren't considered worthy of film during their day. In the digital photography age you just click!-click!-click! until you get the shot. When everyone was shooting film unless you had it in mind you were going to burn a roll or two on detail shots you took your best shots only, well-composed and well-lit. Roster shots of good and poor quality abound from the film era and are easy to find online from a variety of sources. But detail shots of the kind I needed are not so easy to find. If these prototypes still existed in their as-built form today it would be a simple matter of tracking them down and taking some detail photos.

That's actually how the story ends for the National Uni-Truck II. There is a single example of a Front Runner equipped with National Uni-Truck II trucks at the National Museum of Transportation in Kirkwood, Missouri, TTOX 130059. Detail photos of this car provided the information I needed to create the CAD model of the trucks that I ended up printing and offering for sale in my Shapeways store.

3D printed National Uni-Truck II trucks with Intermountain wheels installed on Walthers Front Runner

With the Norfolk & Western U30Cs, C30-7s and C36-7s I wasn't as fortunate finding an example to photograph. I'm not certain on the disposition of all of these locomotives, but many that I've found were shipped overseas after their useful lives here in the United States. Once they arrive at their destination it's not uncommon for them to be converted to a B-B B-B configuration and have the C trucks discarded. I put out a request for photos on discussion forums and email lists a few times over the years but I didn't get a response. That is until the very end of 2017 when Jay Barnaby and Scott Marion hooked me up with some detail photos from their collections. These turned out to be the shots I needed to create 2D drawings.

Some discussion on this topic with Andy Harman was very helpful, too. With the straight-on shots taken care of it became a priority to determine the depth of the features: how much did the brake cylinders protrude from the sideframes, how far did the reinforced section over the center axle protrude, and so forth. More photos were shared and analyzed. And finally in the midst of reverse-engineering the Atlas sideframes to create a drop-in fit of a sideframe I had enough to develop the 3D model.

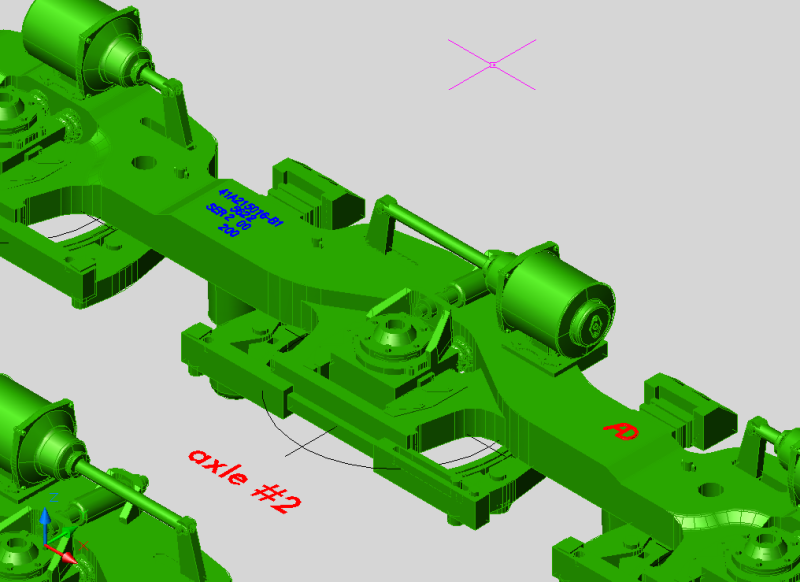

Here's where I screwed up (there's always that part): I created what may be a perfectly reverse-engineered 3D model of an Atlas GE three axle sideframe. Then I proceeded to install brake rigging on the base sideframe model that fouled the copper pickup and bearing strips that held the axle ends in place, thus preventing the installation of the printed sideframes. Well, that's what prototyping is for! (that's what I tell myself when I screw up with a design) What I should have done is create a 3D model of the truck with the copper pickup strip and checked the fit of the sideframe into the truck model in CAD, not after printing the design. Fortunately, I didn't have to modify the back side of the sideframes much and there was still enough material to hold the brake shoes and levers in place after I removed the material fouling the copper strips. I immediately revised the CAD files to remove this interference.

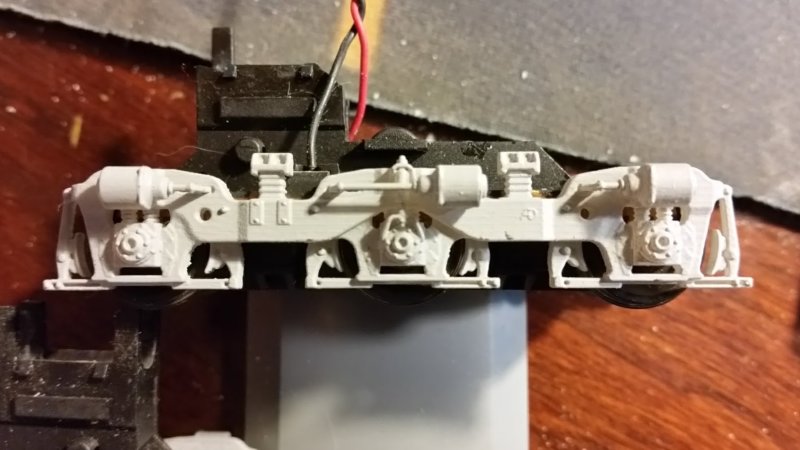

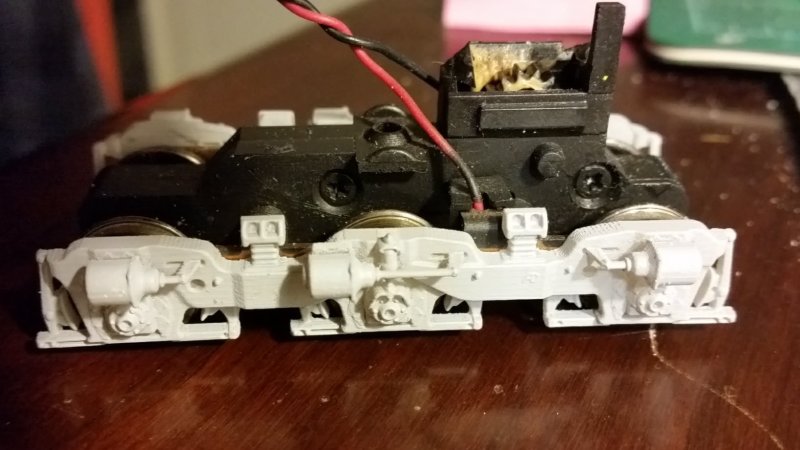

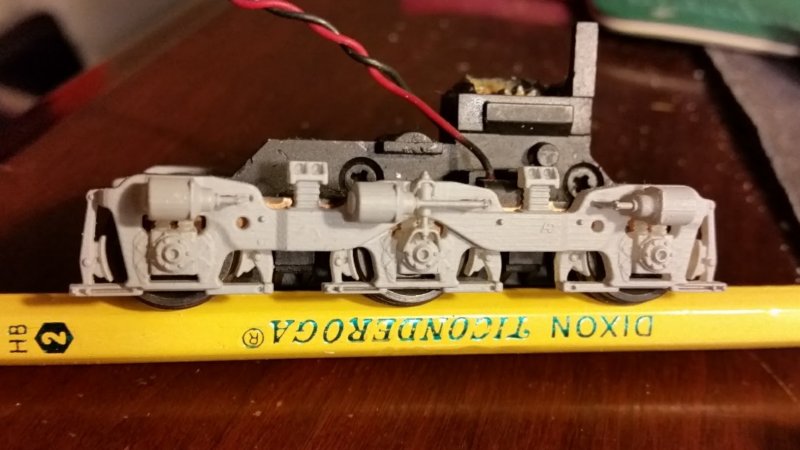

First printed prototype U30C and C30-7/C36-7 sideframes

Spending all this time working on these clasp sideframes helped me get to know both the Atlas model and the prototypes pretty well. One thing I found interesting about the Atlas model -- and I'm not sure what the reason is for this little nugget of joy -- is the axle spacing in the C truck found on the U33C, C30-7 and U30C. I'm sure it has to do with the prototype of the U33C or C30-7 trucks originally tooled in the 90s by Atlas. The difference is so minor that it probably just wasn't worth addressing when it came time to release the U30C. But it is significant enough that putting the wrong sideframe on the wrong truck will result in a sideframe that won't fit without modification. You'll also notice the bearing detail isn't centered on the center axle and wheelset.

On freight cars there is a B end and an A end. Looking at the B end you have a left and right side. Axles are numbered from the B end to the A end. Similarly, locomotives have a front and a rear. The front is designated by a letter "F" stenciled near the stepwell on the sides of the locomotive nearest the front. Ever the oddballs of the bunch, some Norfolk & Western and some Southern locomotives had their long hoods designated the front, which is in contrast to nearly every other railroad. Fortunately on these GE six axle units the front is the short hood where the operator cab is located. So, when you're looking at the front there is a left side and a right side. Axles are numbered from front to rear.

The prototype uses trucks with a wider spacing between axles 2 and 3 and a narrower spacing between axles 1 and 2. On the rear truck this arrangement is mirrored on the U30C and C30-7, with the greater spacing being between axles 4 and 5 and the lesser spacing between axles 5 and 6. The prototype C36-7 has the same front truck axle spacing as the U30C and C30-7, but the rear truck is reversed. It is not mirrored by the fuel tank. Instead, the front truck is identical to the rear truck. That is, the distance between axles 1 and 2 equals the distance between axles 4 and 5. Likewise, the distance between axles 2 and 3 equals the distance between axles 5 and 6.

The axle spacing on the model is just like the C36-7. This means on the model there is a distinct front truck and a rear truck; the axle spacing is not mirrored by the fuel tank.

If you look at prototype photos of U30Cs and C30-7s, the brake cylinder over the center axle points toward the fuel tank and toward the brake cylinder over the axle nearest the fuel tank. The axle spacing is greater between the two axles with brake cylinders pointing at each other than the spacing between the two axles with brake cylinders pointing the same direction. So if you're following this convoluted description, there is a problem. The axle spacing of the rear truck on the Atlas model will not work with the U30C and C30-7. The Atlas model is actually perfectly set up for the C36-7 since the brake cylinder over the center axles points toward the rear of the locomotive and the axle spacing matches the prototype. But to accurately model the trucks on either a U30C or a C30-7 the rear truck must be a mirror image of the front truck. The easiest way to do this is to replace the rear truck with another front truck. Fortunately, these truck gearboxes are easy to come by direct from Atlas. [Kudos to Atlas for continuing to make parts available and for making them inexpensive. I owe a lot of my GE kitbashes to being able to get Atlas parts.]

I figure that of the handful of others who wish to model N&W U30Cs and C30-7s, only a few will be willing to swap out the rear truck for another front truck. So for those who want to keep the drive stock and simply swap sideframes, I've made a version of the clasp sideframes set up to fit the Atlas drive as-is. For those who want to go crazy and swap rear trucks, I've made a version for them, too.

Finally, here is an image to describe the problem and solution. The sideframes depicted below illustrate the modified parts designed to fit an Atlas model that has not been modified with a front truck replacing the rear truck.

To accommodate the model, the sideframe depicted in the bottom of the image has been modified to match the axle spacing but have the general arrangement of the prototype. You can see the slight difference in distance between the brake cylinder cutouts over axles 2 and 3 and over axles 4 and 5, with 4 and 5 being closer together. On the prototype C30-7 and U30C, the bottom truck should be a mirror image of the top truck.

I'm exhausted from explaining that. You can imagine how exhausting it was to discover during the design process and create a solution for it.

After going through all that, I'm going with the extra front truck on my C30-7 model. Here are the C30-7/C36-7 sideframes:

And here are the U30C sideframes:

Printed Adirondack sideframe compared to Atlas GSC sideframe

One benefit of working up these sideframe designs with such a limited audience is I realized this basic Adirondack design was found elsewhere, namely on early C30-7s purchased by Union Pacific and the C36-7s purchased by Missouri Pacific. It didn't take much effort for me to modify the design to match each prototype.

screenshot of Adirondack sideframe CAD file as seen on early Union Pacific C30-7 locomotives

screenshot of Adirondack sideframe CAD file as seen on Missouri Pacific C36-7 locomotives

One of these days I'll try to run down all the prototypes that used some version of this basic Adirondack truck casting...

Very impressive fr8kar! I myself am looking for sideframes to do an ATSF C30-7. I have and Atlas C30-t but it came with Atlas sideframes. I think I need the GSC but the Adirondacks you modeled look spot on as well. Are they for sale in your Shapeways store? Or elsewhere?

ReplyDeleteThanks,

Paul