Ah, vehicle models! The unsung heroes of the model railroad landscape. The supporting cast backing the stars of the show. As scenery or even loads these models seem to get far less attention. Let's face it: most modelers are willing to let anachronisms, detail inaccuracies, and even a lack of detail go just to have a reasonably close version of a particular vehicle model.

There are some who look at the vehicle models as the real stars and the trains are just the backdrop to the action on the highway. In other scales these modelers tend to be separate from the railroad modelers; only in HO scale would these folks be considered a subset of the larger model railroad hobby. But there are many who push the limits and take HO scale vehicle modeling to the forefront.

For me the Athearn Freightliner cabover kit was a great introduction to HO scale vehicle modeling. It was very cheap compared to the giant 1/25 scale models and though it was a simple model it was proportioned beautifully. I remember clearly the first time I saw Leonard Frere's models in the HO Model Railroading Handbook:

The heritage of that daycab Freightliner straight truck and trailer was obvious: Athearn's tractor and Fruehauf reefer van models. The creativity behind this kitbash started me off on a path of bashing my own models as a teenager. To this day it almost depends on which way the wind blows whether I'd consider myself a railroad modeler first and a vehicle modeler second or vice versa. For the past few months it's been decidedly skewed toward vehicle models.

Dumps

At the inaugural Texas Railway Modeling & Historical Society prototype modeler's meet in June 2021 I got to meet a bunch of local model railroaders of the same stripe as me: guys who not only count rivets but measure them, people who are experts in their field of interest, folks who design and build and paint and print their creations.

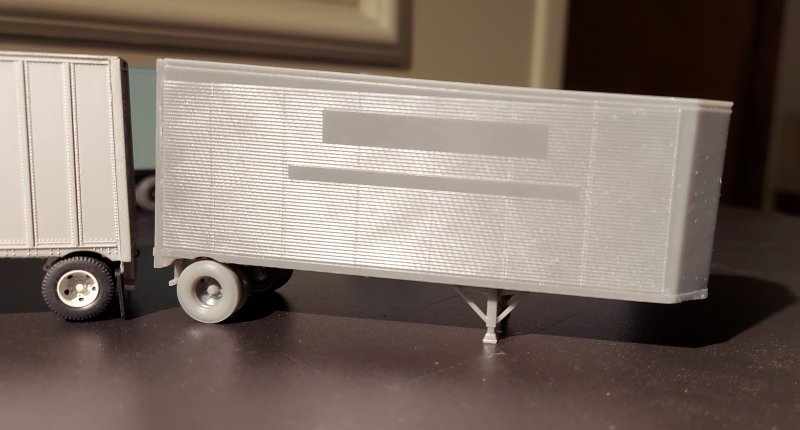

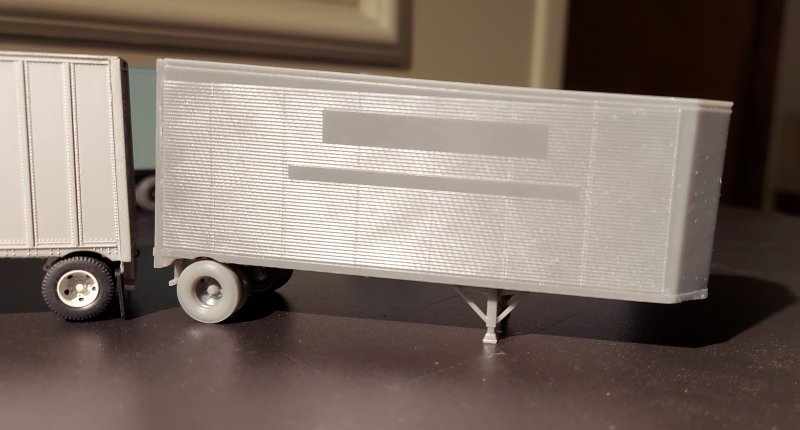

I met Marshall of MP Scale Models who had several N scale models displayed that he 3D printed. These were resin prints that were so much smoother and more finely detailed than the acrylic prints I'd been getting from Shapeways. It turns out he lives close by and we have some common interests in prototypes that bridged the divide in scale. Soon the conversation turned to printing my designs and he felt confident he could print the trailers I asked about. A few weeks later he handed me this:

|

| 1979 Fruehauf 32' Dump Trailer kit fresh off the printer |

I took this photo as soon as Marshall put it in my hands. I could already tell the material was so much smoother than what I could get from Shapeways. The extended hydraulic ram was straight and the wheels looked amazing.

It didn't take long before I had the parts primed and assembled. Here it is in the raised position then with the hydraulic rams swapped out in the highway position.

|

| A similar truck and dump trailer at Flynn Yard in Oklahoma City |

Although these aren't cheap to print, Marshall was able to give me a much better price than I could from Shapeways. And the quality difference is just ridiculous, truly on another level. These prints are gorgeous!

Shortly after I printed these first samples I found the elusive 39' version of this dump trailer for sale on an auction site. The photos weren't great but they were good enough for me to count the ribs and confirm that lengthening the trailer would be a simple slice and dice. In no time I modified the CAD file to model the longer version of this kit.

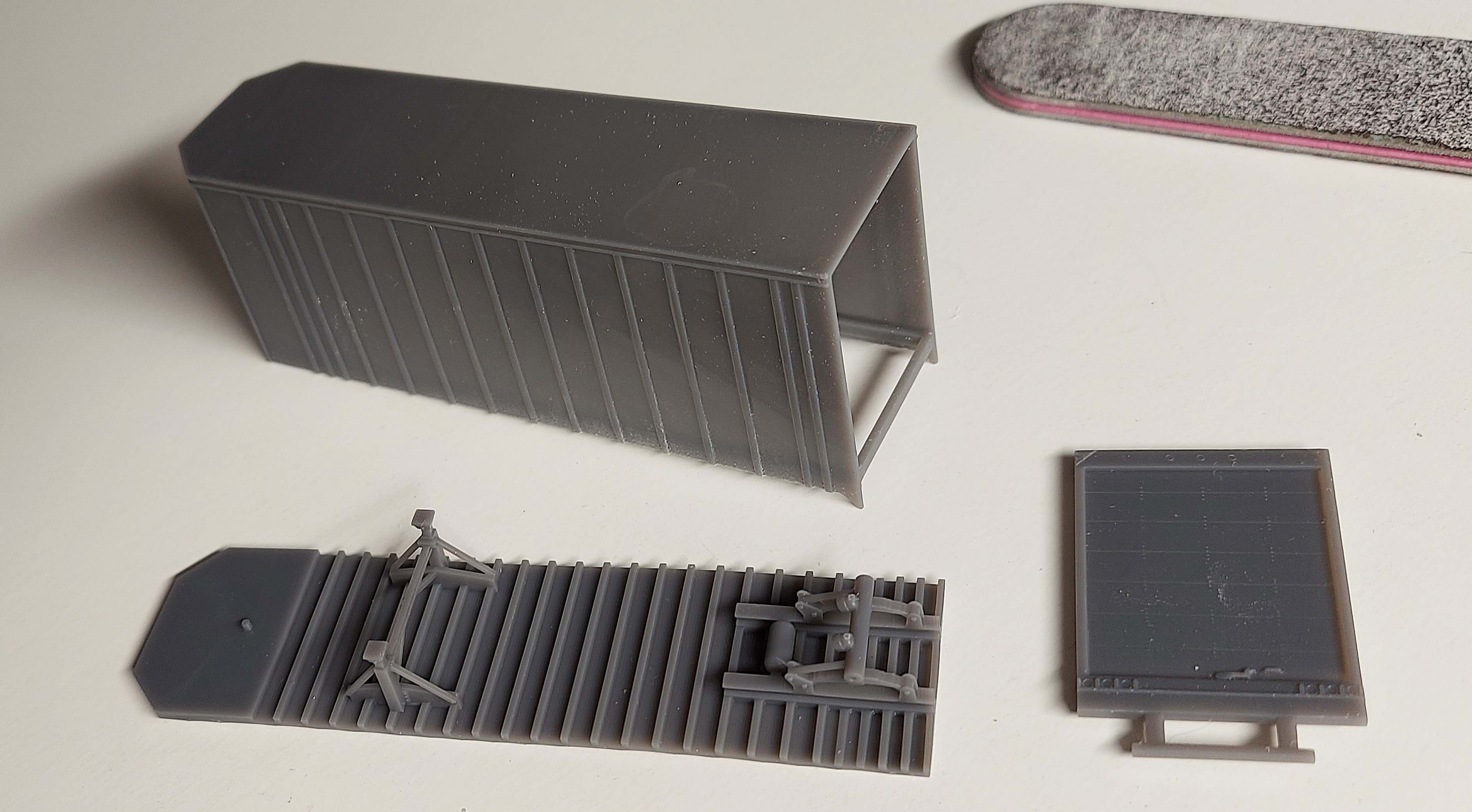

When I wrote the instructions for the dump trailer kit it occurred to me many modelers will want to assemble the model with the bed lowered in the highway position and won't want to go to the trouble to make the model positionable with interchangeable hydraulic rams (sorry, I can't get those to operate!). So, to speed up the assembly of trailers that will only ever be in the highway position I came up with a variant that is printed in six parts: four tire/wheel parts, one spring suspension part and one "everything else" body part:

|

| The "one-piece" 39' trailer model with unpainted tires |

Pups

After this success I had to try a few other ideas out, and none was more exciting to me than the bullnose pup trailer. When I first drew these and uploaded them to Shapeways I was so excited. But then I saw the price. Outrageously expensive! Unfortunately it was to the point where I could maybe have one or two, but a warehouse dock full of them? No way.

The worst part was I'd made a few mistakes in that first draft and the model needed to be repaired manually. I fixed the wheel wells and the position of the rear axle but I couldn't do much for the fact that it's a scale foot too short. Ouch. Here's the first Shapeways print with my custom decals printed by FedEx Office 😮😁 and the revised version printed by Marshall below:

|

3D printed flat kit from Shapeways, warts and all

|

|

| First print from MP Scale Models |

The basic bullnose trailer drawing was based on a wedge pup built by Trailmobile, but with a few minor changes it could fit in with prototypes built by Road Systems, Strick and Evans Monon among others. Motor carriers who operated these bullnose trailers include: Transcon, Pacific-Intermountain-Express (and successors Ryder/P-I-E and P-I-E Nationwide), ANR through Garrett Freightlines and Graves Truck Lines, Brown Transport, Consolidated Freightways, Roadway Express and Santa Fe's SFTT.

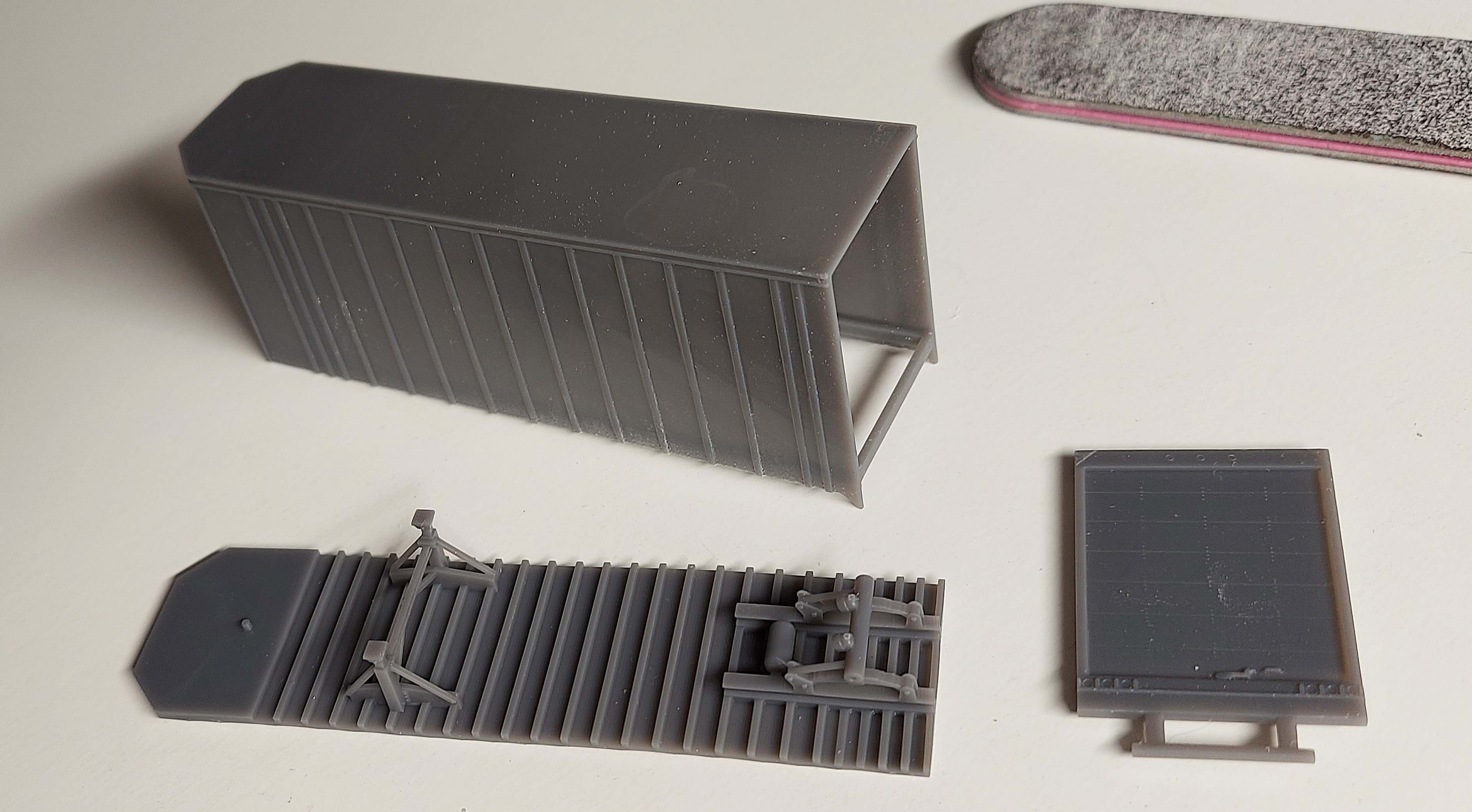

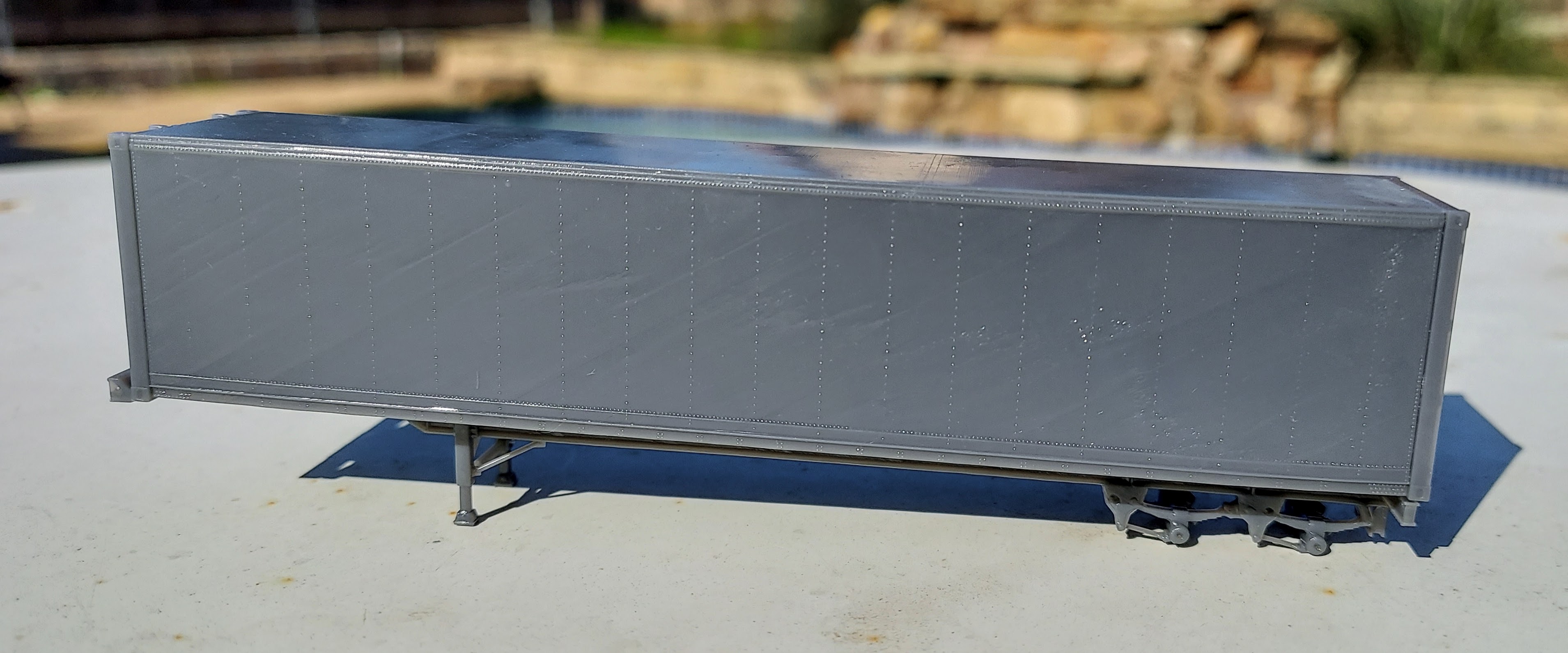

Naturally there were differences between the versions each of these carriers had and for those with larger fleets there were even differences within the fleet. So it wasn't long before I found myself cataloging these options of noses, sides, wheel well cutouts, doors, pintle hooks, taillights, suspension and landing gear. I figured the easiest way to break these variations down was to print the doors and floors separate from the body, that way those parts could be combined with each other to form unique models.

|

| The basic kit |

Here are some examples of variations on the printed models:

I was talking with my friend Bob of

Masterbilt Models about the possibilities with these variations, how it reminded me of when I'd take the girls to the mall and they'd come home with a stuffed animal they chose and helped make. A modeler could select a door, a floor, the body and the type of wheels for a trailer they wanted to model. The idea for Build-A-Pup was born.

This same idea can be extrapolated to other trailer designs and I've got a few in the works. Fruehauf trailers have always been fascinating to me since I was a kid building 1/25 scale models. Those AMT kits seemed to have every variation Fruehauf made covered in model form back in the 70s and 80s, so it didn't take long to become familiar with those details that made a Fruehauf trailer stand out. After drawing up so many bullnose pups I moved on to drawing Fruehauf wedge and straight-floor pups. I've only just printed out two examples, but like the Trailmobile pups the possibilities are practically endless.

|

| All done except for the wheels |

The Roadway trailer is 102" wide and it's the first one of the wedge trailers I've widened from the 96" wide CAD file. After applying the Microscale decals and seeing the columns of rivets relative to the lettering the mistakes I made cutting and splicing the CAD file are obvious. That's always how it goes!

The Central trailer represents a prototype cut down from a 40' x 96" Z-van trailer for P&D service. Bob had the Central decals made and they look fantastic.

Flat-decks and Ragtops

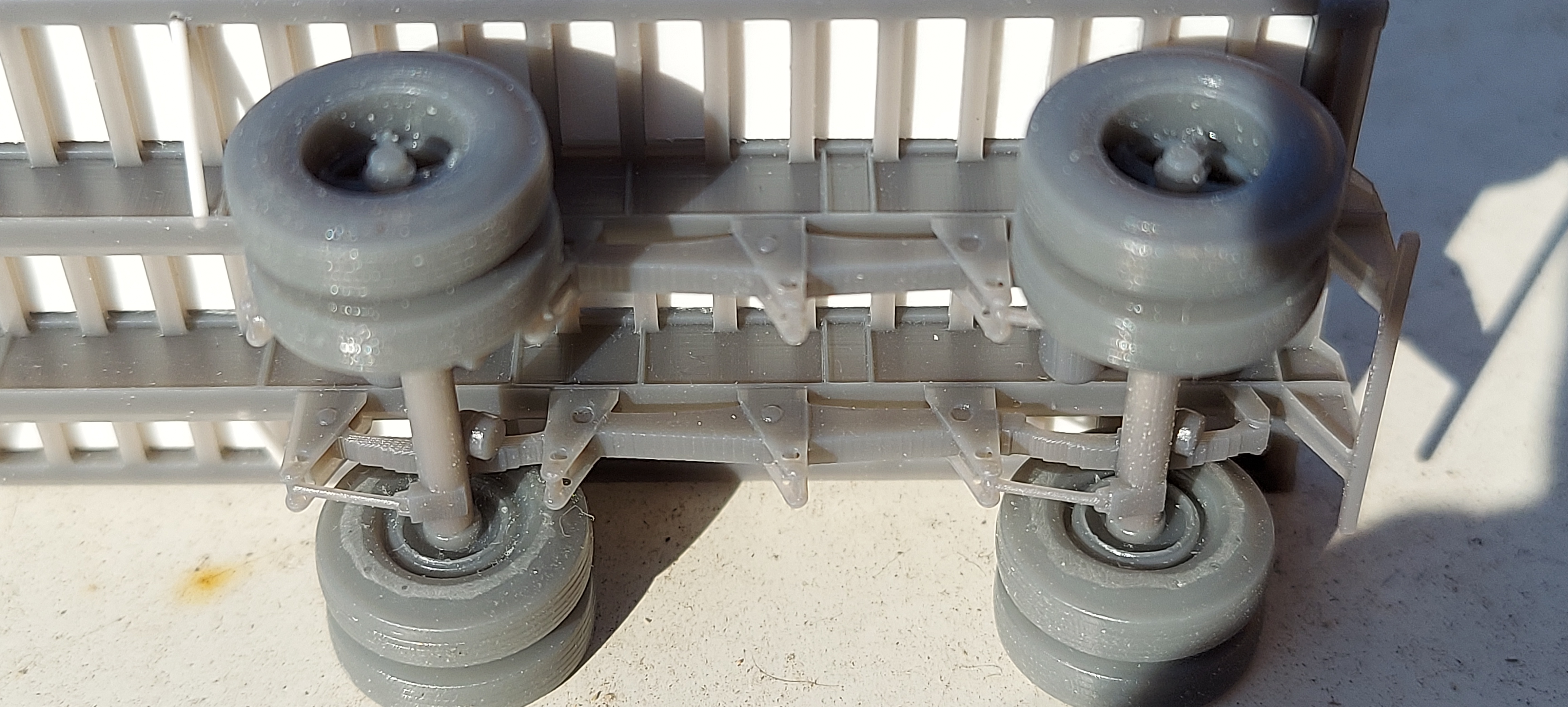

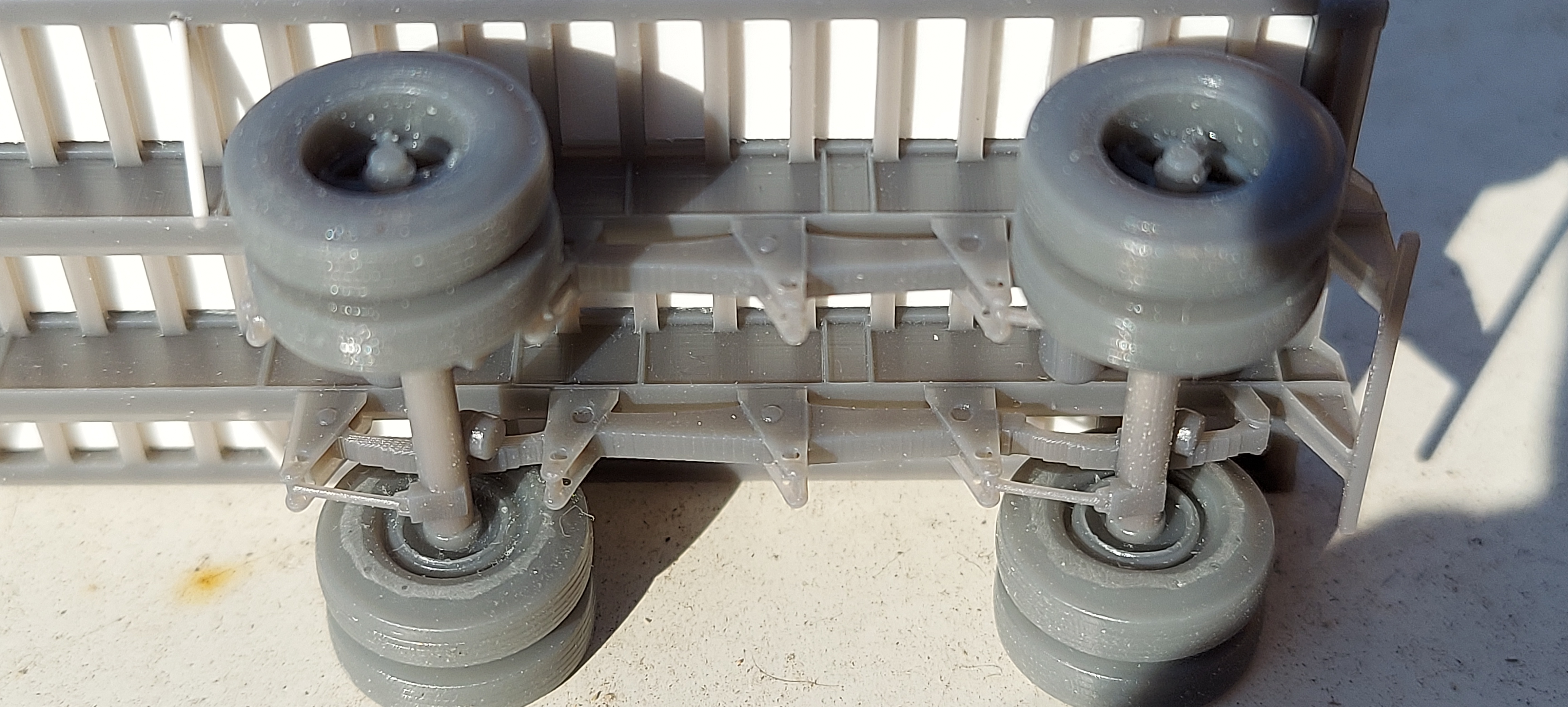

This brings me to flat deck trailers. Thinking back to those AMT kits there were some really cool flats including one that telescoped into a long version for oversize loads. While searching for photos of those online I stumbled across some more straightforward Fruehauf designs. The basic trailer is the same but the suspension setup can be changed from a fixed spread to a sliding tandem. Fruehauf used modular suspension components to build up both their fixed spread and sliding tandems so once I had the components drawn I started "assembling" them. The shape of the components changed over time from an early triangular shape to the later spade shape.

|

| Late sliding suspension |

|

| Early fixed spread suspension |

Another project I just had to take on was a staple in the TOFC fleets of old: the ragtop van. Again, the Fruehauf version was a no-brainer for me since I'd drawn the body elements for the Fruehauf pups and the frame and suspension parts for the flats. This one is crying out for Santa Fe or Rock Island decals:

Gensets, Chassis and Cans

Speaking of decals (and realistically this deserves its own post so I'll work on that), I was all set to order some decals for these trailers and some other vehicle details last year. I had begun putting together a package illustrating the details I wanted captured in the artwork and some examples of the fonts and things that would be needed to complete the artwork. While describing this project to Marshall he suggested I try to create the artwork myself in Inkscape, a free vector software, that way I could get the details I wanted without having to iterate the design with a third party (in other words, save some dough!).

So I downloaded Inkscape and started watching some tutorials. In no time at all I had some finished artwork and began working with

Bill at PDC to print the decals. So what you see above on the bullnose trailers is the result of that process. I not only was able to create the artwork for the models on my terms and to my specifications, but I also found that I really love drawing decal artwork and creating fonts. Who knew?

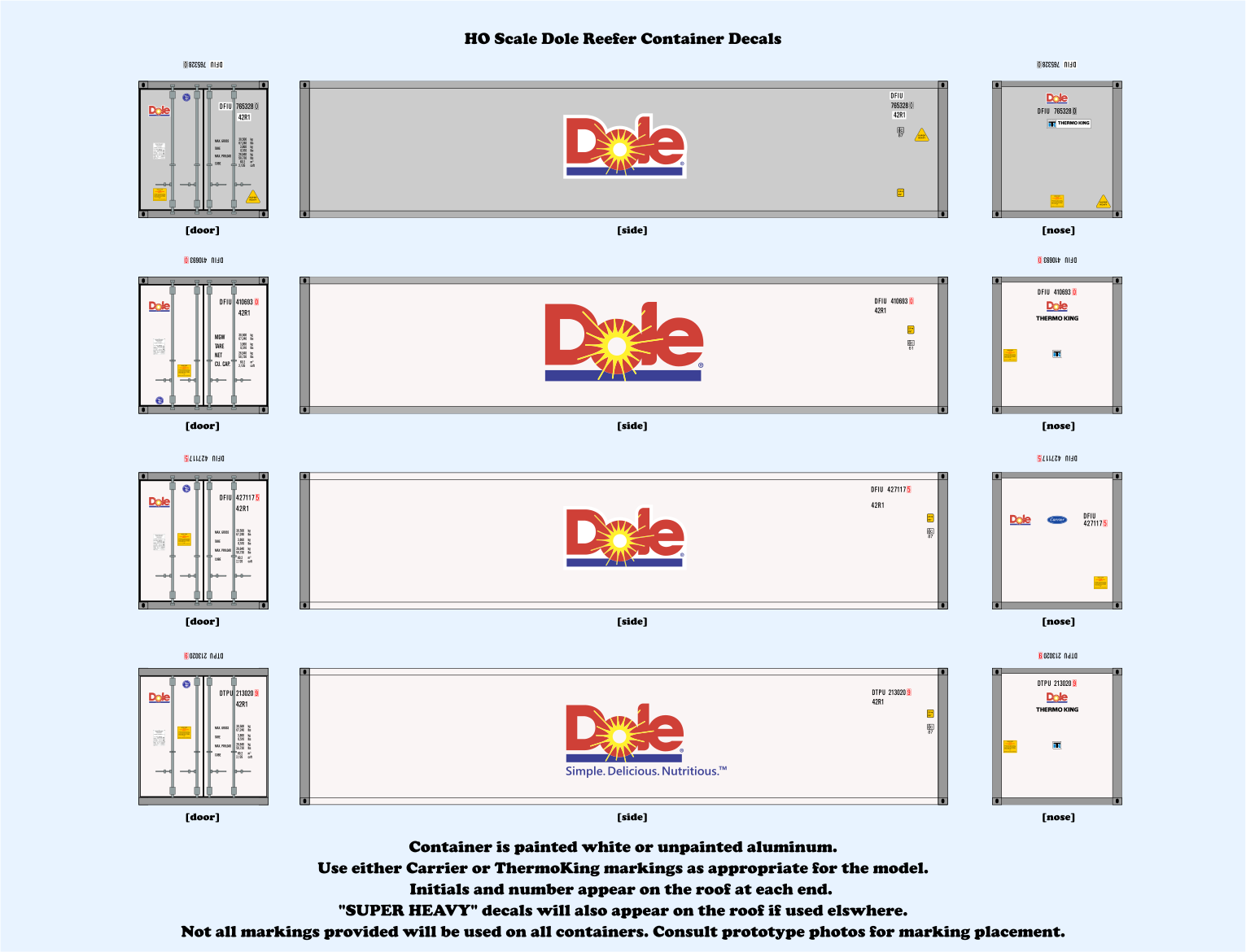

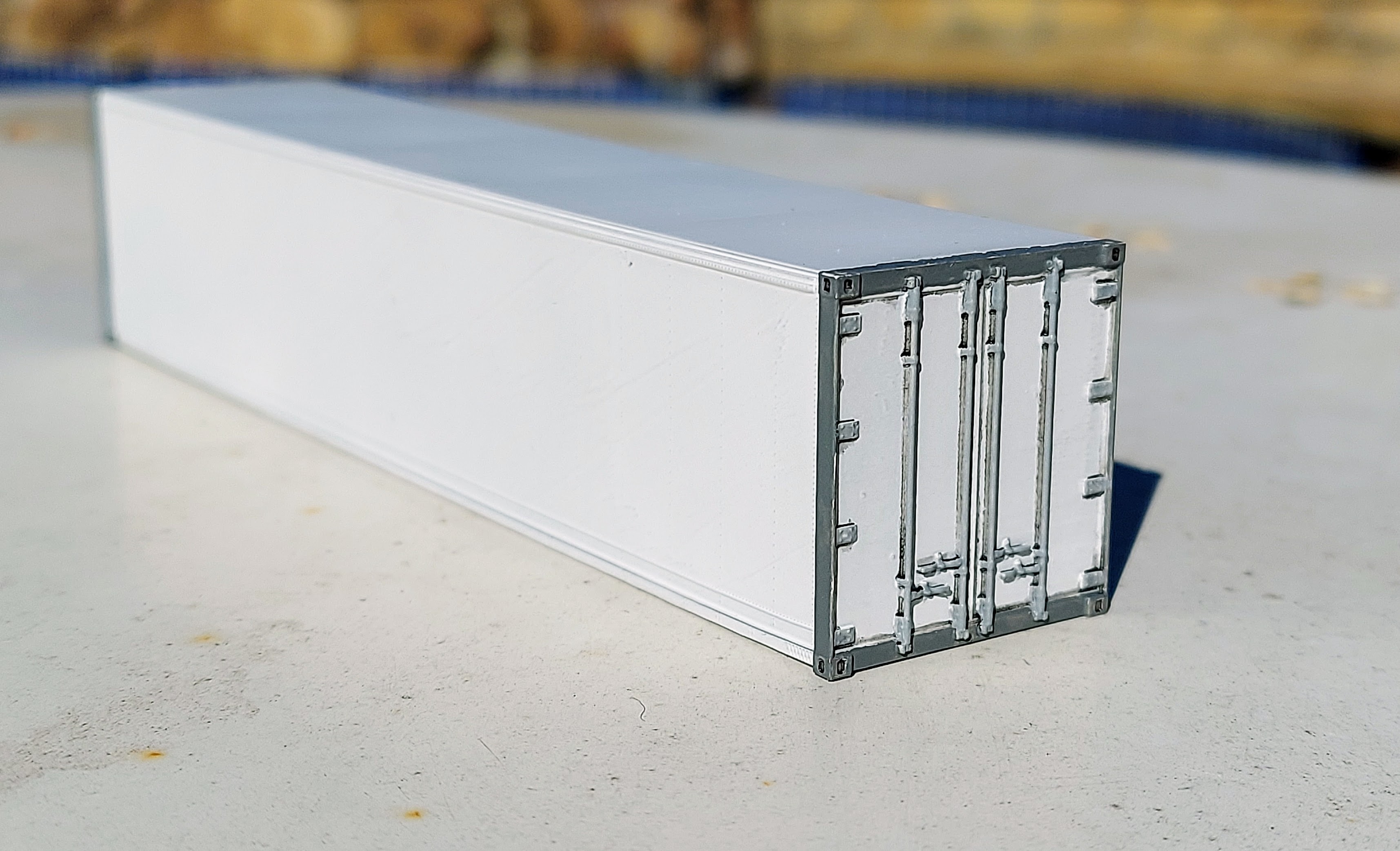

Learning how to make decals has opened up some projects I've wanted to do for ages. Honestly, now I have more things on my plate than I ever expected. But that's a good thing. First of all, reefer containers and more importantly, reefer containers filled with tropical fruit. Those little clip-on gensets keep the reefer units powered to keep the containers cool in transit:

These little guys had been on my list for a long time. After finding some repair manuals with isometric drawings I was able to create a CAD file. Decals soon followed.

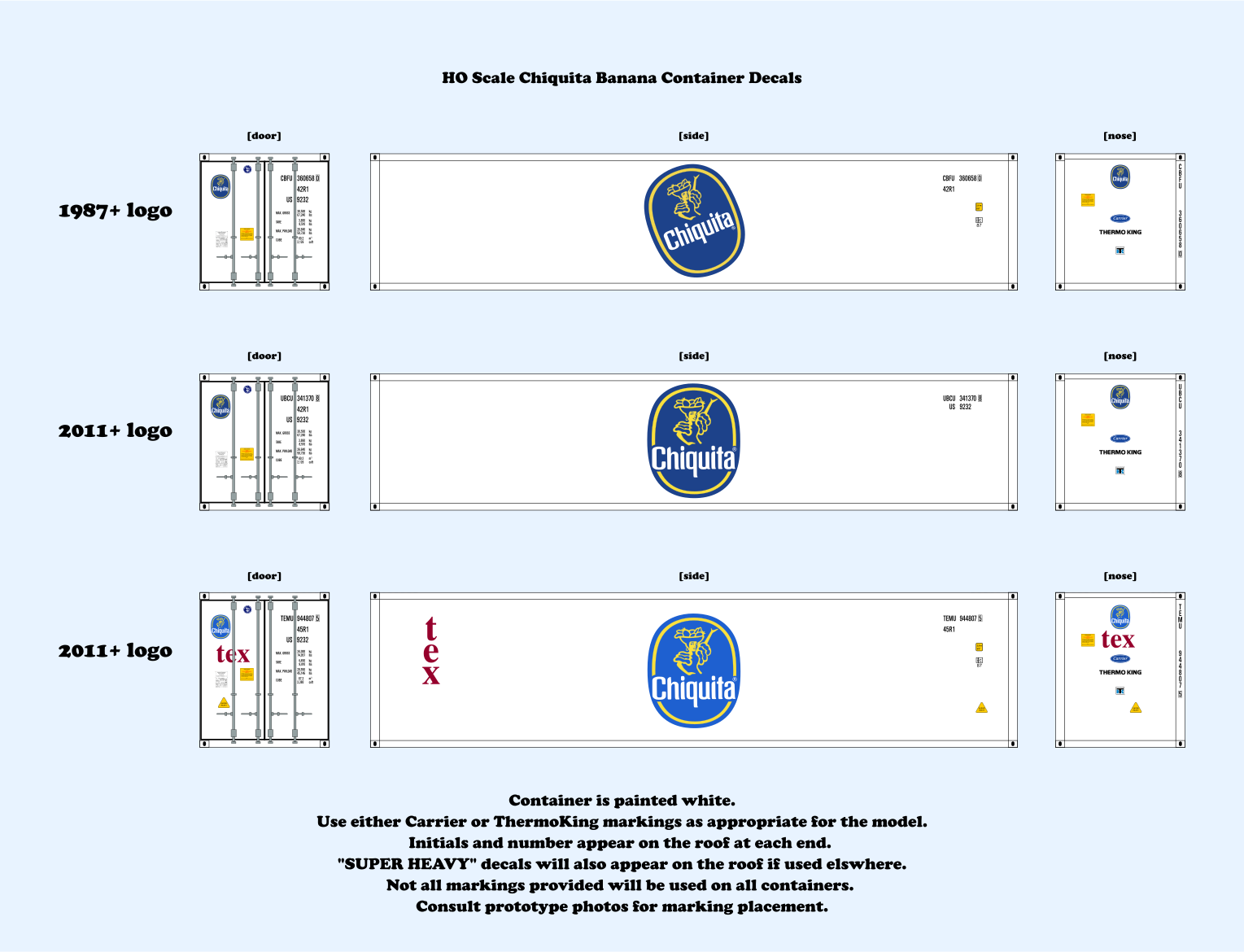

You can get Con-Cor and Walthers reefer containers lettered for Dole and if you're lucky you can find the Microscale Dole container decal set. Likewise, if you look you can find the Con-Cor container lettered for Chiquita but they are not easy to find. So I decided to correct that problem and make my own Chiquita container decals.

A few months later and I had created artwork for Dole containers.

|

| 3D printed gensets and some Chiquita containers with custom decals |

But that wasn't enough, because Dole containers typically move on Dole's own Fruehauf chassis with gensets mounted below deck, so of course I had to draw the gensets...

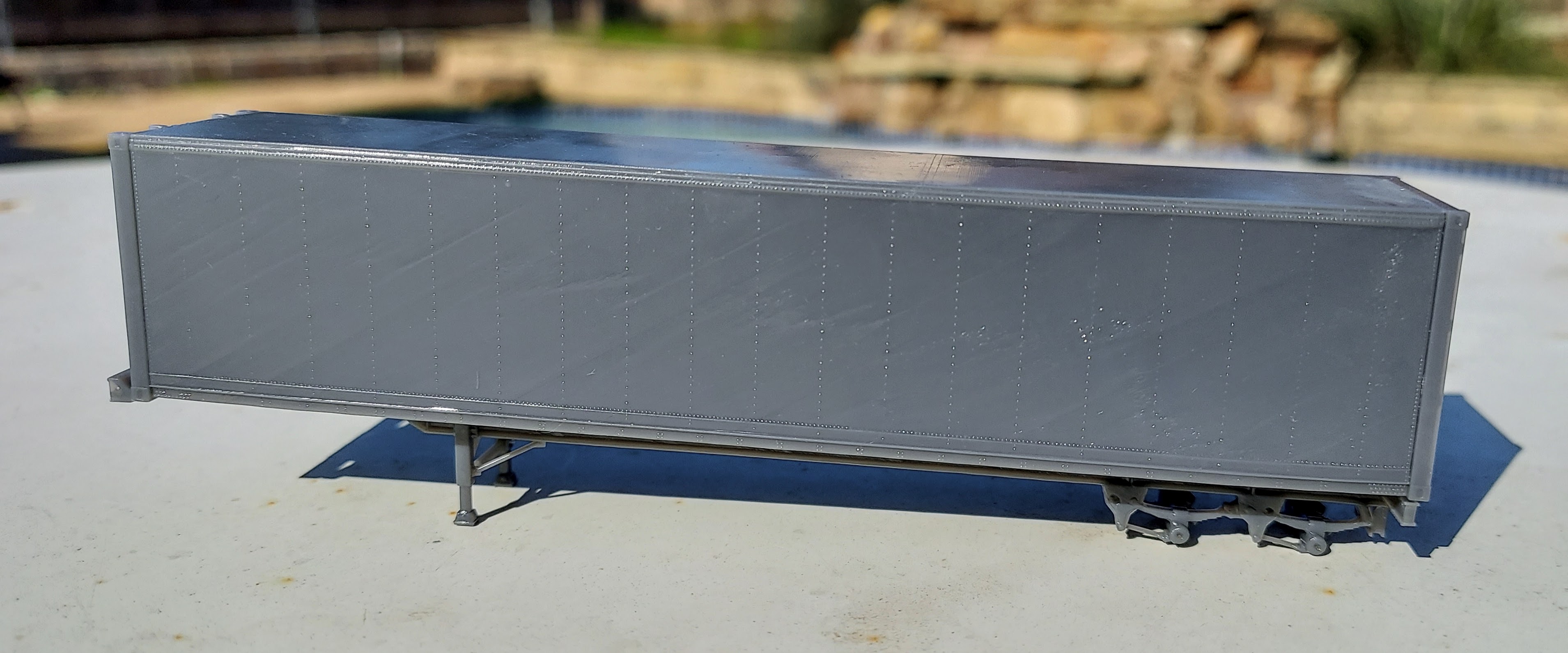

...then the Fruehauf chassis...

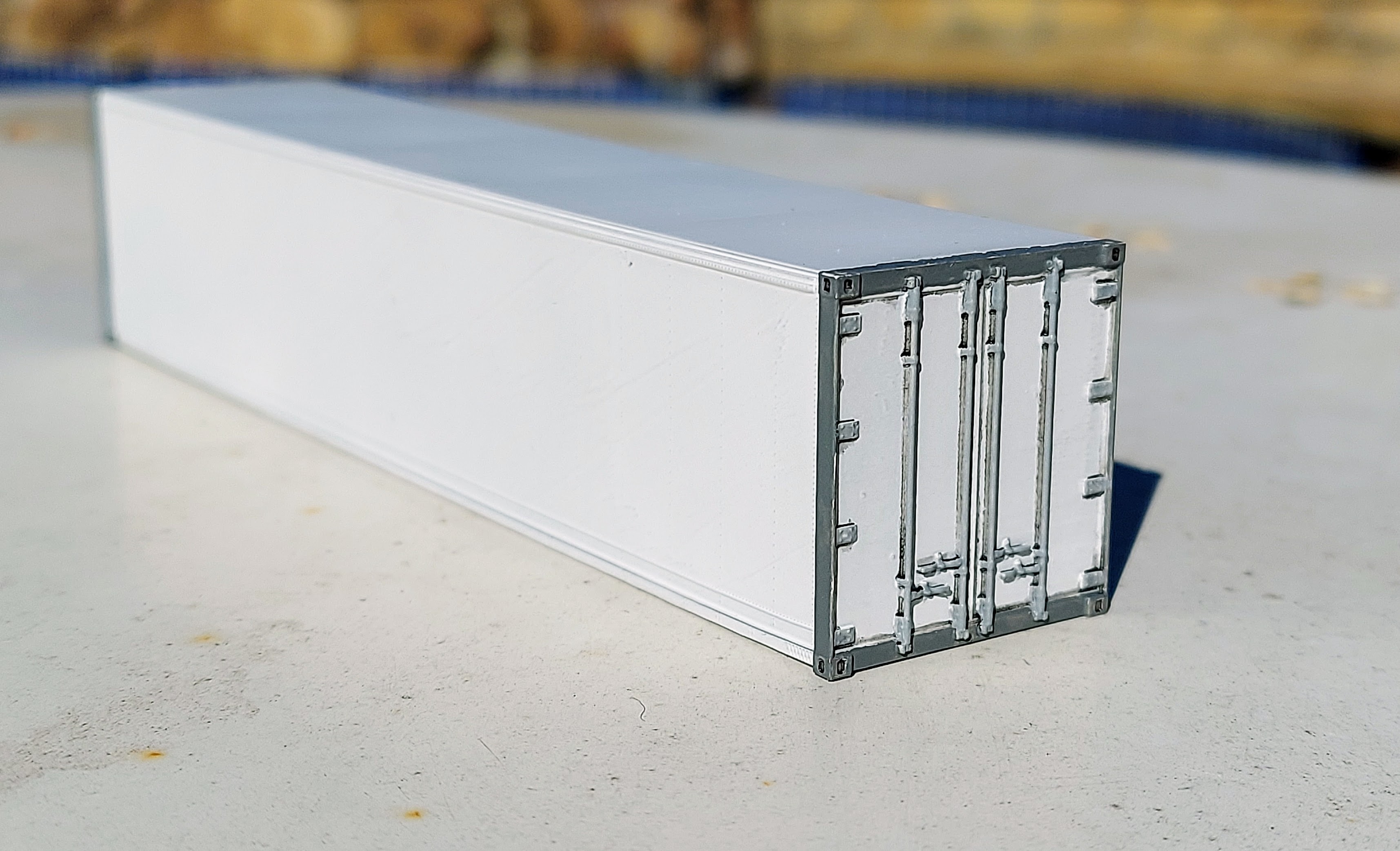

...and finally a Fruehauf standard height reefer container:

This one will be much closer to the real thing than my stand-in made from an American Limited chassis with printed genset and fuel tank and a Walthers hi-cube reefer container:

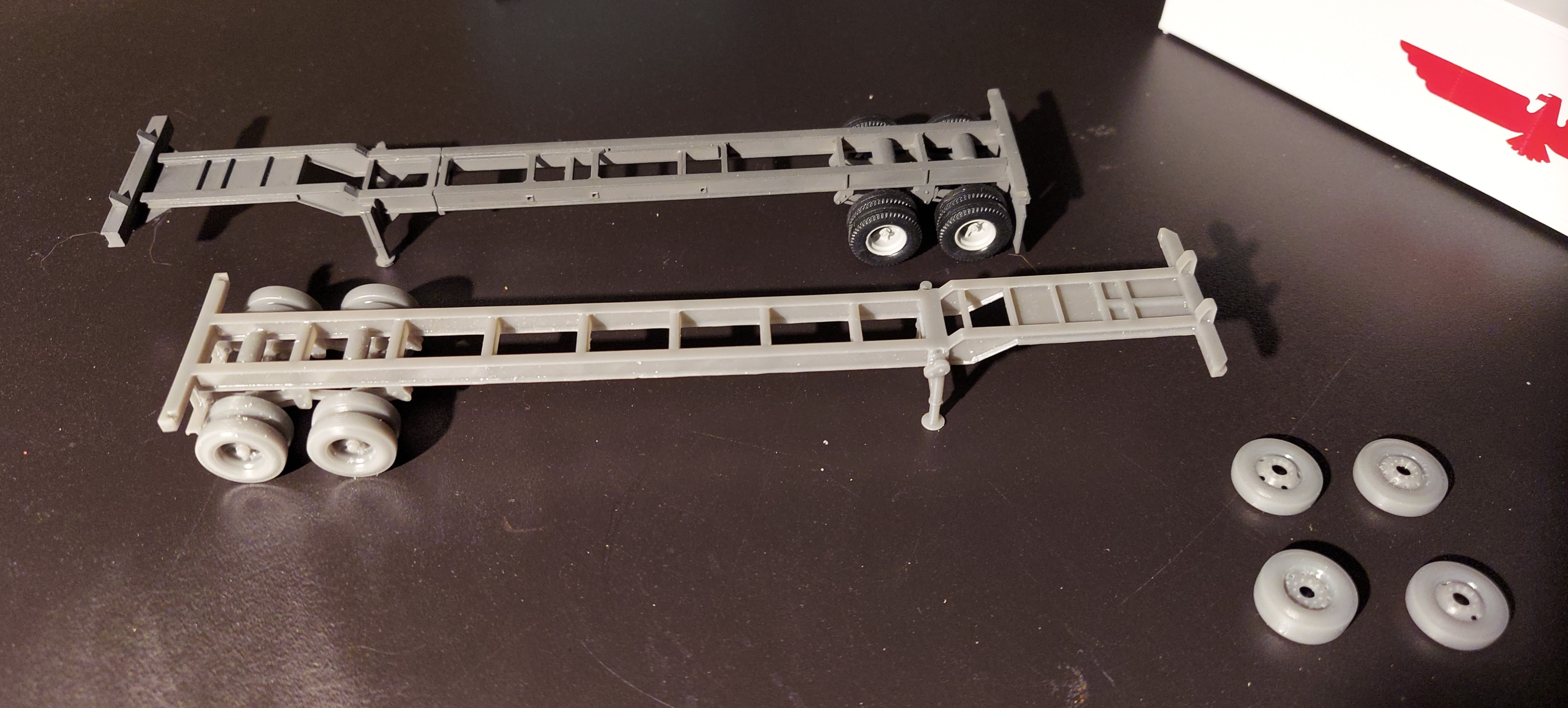

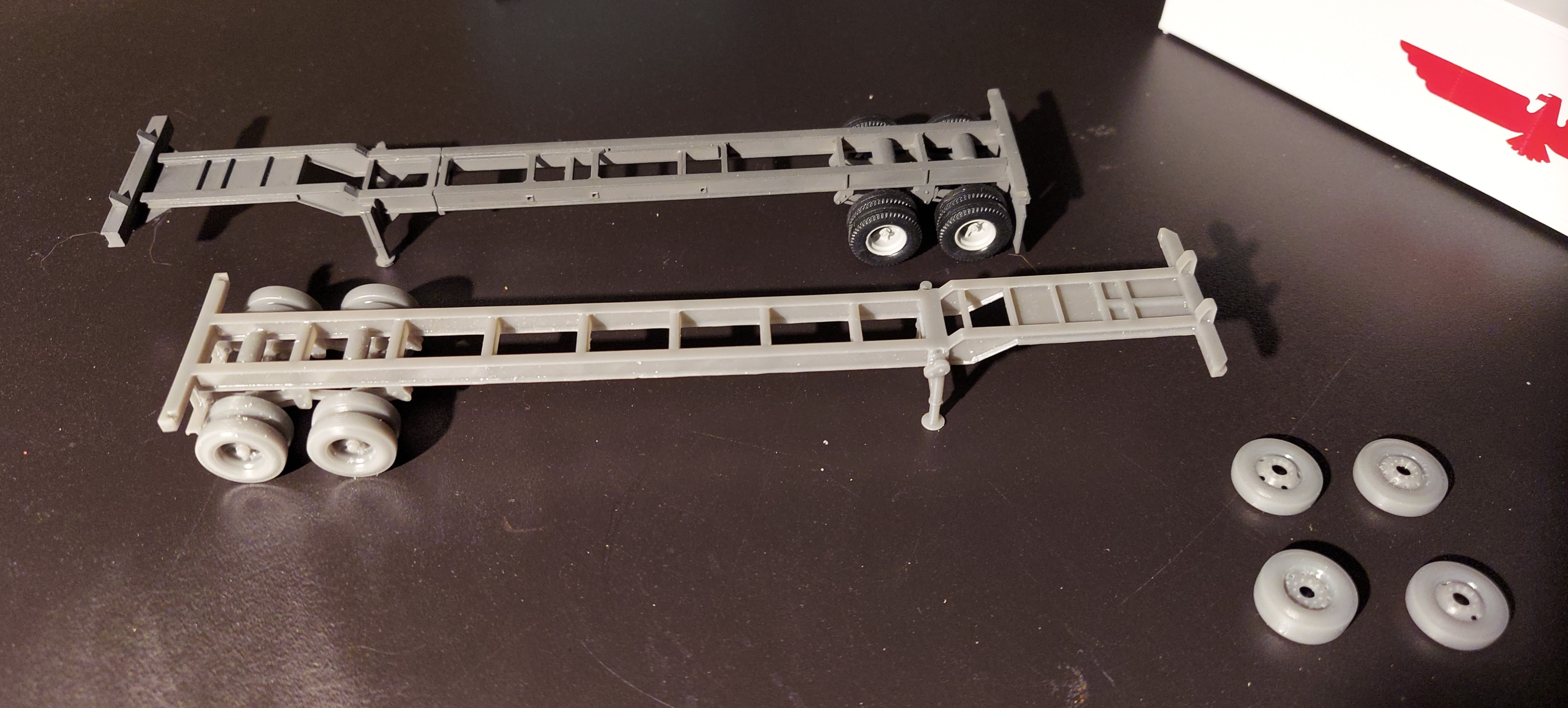

Going back in time a little bit, around the time I printed the Fruehauf dump trailer, I had also printed this Gindy container chassis, based on

photos posted by Ed Sutorik. This chassis helps add a little variety to the fleet with something that's appropriate for the 70s through the 80s. It doesn't hurt that they're fairly inexpensive to print, too.

|

| 3D printed Gindy chassis in foreground, American Limited chassis in background |

|

| Gindy chassis, Walthers container and ThermoKing clip-on genset |

The Gindy chassis and the Fruehauf chassis share some of the same bones, but there are some real differences throughout. It's the same with the bullnose trailers and the other pup trailers. Those little differences really make the difference. The takeaway is that I can dial in any variation I want to draw and I can print it.

Any variation? Why not?

Well, it's actually kind of the opposite problem manufacturers have when they cut tooling. They are trying to find the most common variants to model so that the tooling can be used across a variety of paint schemes. Many times little compromises have to be made, such as the double row of rivets on this prototype can't be modeled or the different step wells on that model can't be done.

With manufacturing on demand that's not a problem. But where it starts to get out of hand is having dozens and dozens of variations. Chasing down every esoteric detail, defining them and describing them on a model-by-model basis might be asking a bit much. In the case of these containers, chassis and trailers, some things just have to be let go or the project will never end. It truly can spiral out of control.

I can't help but feel optimistic about this endeavor. It's easy to say the possibilities are endless with 3D printing, but... And there's always a "...but" in these discussions. But for an aspiring cottage industry manufacturer -- today's equivalent of yesterday's one-man resin casting shop -- the technology is finally good enough. Even inexpensive hobby printers can achieve a resolution fine enough to satisfy the most discerning modelers. In not much more time 3D printers will achieve the same or better resolution than expensive injection-molded plastic.

Another great aspect to manufacturing on demand is the democratizing effect it has. Twenty years ago an aspiring designer had to apprentice as a toolmaker and either be well off himself or be backed by some deep pockets. That's not true anymore. It's possible to design sophisticated models using free software or even old software (ahem, looking at you AutoCAD) on mediocre computers. You don't even have to own a printer -- I'm living proof of that -- but besides those entrepreneurs doing contract printing many libraries have printers available to the public. You don't need an engineering or design background to design 3D models, either. Anyone motivated enough with some basic resources can do it. Like Chef Gusteau says, "anyone can cook!"